18 Peroxyalkyl radicals were identified as key intermediates for the formation of organic products from the n-decane OC. The MSR is a chemical process combining several reactions leading to products with a wide range of chemical natures. The complex reaction system involved in a MSR with various chemical transformations requires a thorough study of the different reactivities of the diesel n-alkanes. 32–34 In the case of thermal cracking, heavier hydrocarbons lead to higher yields of ethylene. It is well established that the reactivity of n-alkanes increases with their carbon chain length when the conversion occurs through gas-phase oxidation, 28 catalytic combustion, 29 acidic-catalysed reaction 30,31 or thermal cracking. Nevertheless, the impact of the reactant carbon chain length on olefin formation and MSR behaviour still requires clarification.

They highlight an increase in the length and the yield of LAOs with n-alkane length. showed the relevance of this technology to produce LAOs. 25–27 In some studies of diesel n-paraffin OC in a MSR, 10,11 Schmidt et al. Alkanes produce mostly olefins, 9,11,12,19–21 while cyclic reactants produce aromatics 22–24 and oxygenated reactants result in oxygenated compounds. of various reactants highlight the dependence of the chemical nature of the organic products on the reactant structure. 10,11,13,15–19 The MSR is then a 2-zone reaction system involving consideration of both the thermal equilibrium and chemical transformation. 11,14 In this homogeneous process assisted by heterogeneous catalysis, complete and partial catalysed combustion of a part of the reactant provides the required heat for the gas-phase formation of olefins by oxidative and thermal cracking. Pt/Al 2O 3) to produce LAOs through an autothermal way. 9–13 Hydrocarbons react at millisecond contact times with a heterogeneous combustion catalyst ( e.g. The oxidative cracking (OC) of hydrocarbons in a millisecond reactor (MSR) appears as a promising alternative to synthesise these raw materials in one step at atmospheric pressure. 3,6,7 LAOs then supply the markets of polyethene, surfactants, lubricants and plasticisers.

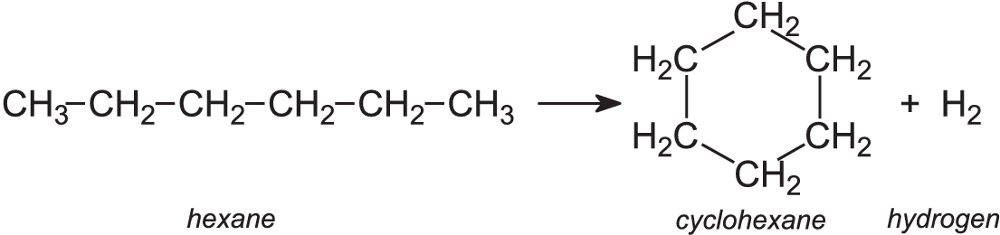

3–5 The chain lengths of LAOs thus extend from 4 to 30 carbon atoms and follow the Schulz–Flory distribution for high-temperature oligomerisation (Gulfene and SHOP processes) or the Poisson distribution for low-temperature oligomerisation (ethyl process). 2,3 This reaction requires high pressures (>10 atm) and is carried out in an organic solvent with homogeneous Ziegler or nickel complex catalysts. 1 The current industrial production involves the steam cracking of hydrocarbons at high temperatures (>750 ☌) followed by ethylene oligomerisation. The global production was 5 Mt in 2017 and should grow in the following years to reach 6.2 Mt in 2024. Introduction Linear α-olefins are key petrochemical intermediates. LAO and n-aldehydes and (ii) a model based on the hydrogen atom abstraction probability for oxygenated compounds, the formation of which does not involve carbon–carbon bond cleavage, i.e. Two mathematical models are able to predict the distributions of organic products: (i) the Anderson-Schultz-Flory law for cracking products, i.e. Furthermore, the LAO carbon chain length tends to be higher when feeding the MSR with larger n-alkanes. The LAO yields increased with the carbon chain length of the reactant from 11.4 wt% starting from n-decane to 20.2 wt% starting from n-hexadecane. The heat provided led to a thermal gradient in the post-catalytic gas-phase and sustained the endothermic formation of valuable linear α-olefins (LAOs). The thermal mapping of the reactor showed the similar thermal behaviour of the millisecond reactor at the steady-state for all reactants, corresponding to the autothermal operation of the combustion catalyst in the range of 440–550 ☌. The oxidative cracking of n-decane, n-dodecane, n-tetradecane and n-hexadecane was assessed at millisecond contact times on a platinum catalyst at a C/O molar ratio of 1.8.

0 kommentar(er)

0 kommentar(er)